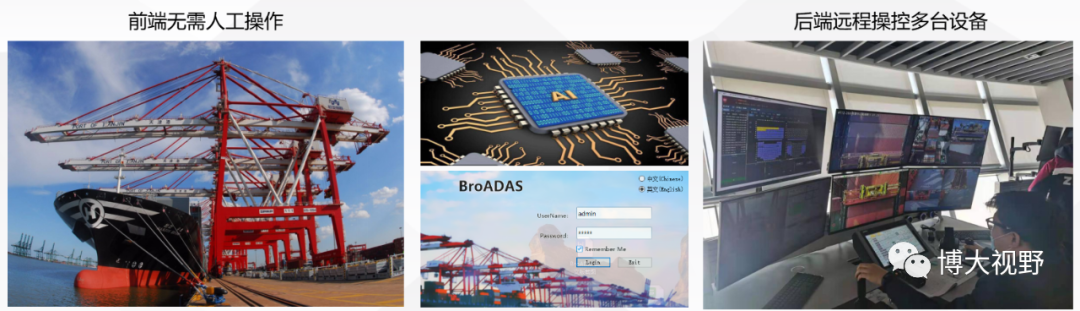

Haifa port of Israel, an important landmark along the Belt and Road, will become Israelundefineds largest container terminal when completed. Broad Vision (Xiamen) Technology Co., Ltd. designed BroADAS intelligent auxiliary driving system for the 8 automated shorecranes. As of mid-October this year, the shorecranes and other equipments have been fully shipped.

Wu Nanhai, founder and general manager of Broad Vision, described the above-mentioned system as a "strong and intelligent eye", "not only the hardware can meet the requirements of the harsh environment of the port, but also we have designed visual AI algorithm, remote driving system and equipment management system so as to make port more safe, more intelligent and more efficient" said Wu Nanhai.

It is reported that the system is developed based on "outdoor heavy industry cameras + ADAS" concept, and is the first in the industry . This artificial intelligence program has also aroused investorsundefined concern and was selected into the "2020 Xiamen Torch Entrepreneurial Growth Camp".

Service the smart ports from security perspective

In the early stage of business, Wu Nanhai chose to start from the crane safety market. Before founding BroadVision, Wu Nanhai used to work in Europe crane giant Huisman, the companyundefineds sound safety management mechanism influenced him a lot. "We want to introduce the safety concept of European companies,service the smart ports from security perspective to reduce accidents in production operations”said Wu.

Since then, Wunanhaiexpanded the business scope into cranes, tower cranes, forklifts, trucks. In 2018, the wave of artificial intelligence swept, Wu Nanhai decided to seize the opportunity of smart port development and be dedicated and focused in safety area of smart port.

In order to solve the safety problem of port mobile machine (reach stacker / lifting crane), Wu Nanhai’s team did in-depth research and found that the traditional mobile machine uses radar detection, which is not accurate - the system triggers alarms for any objects getting close to the crane, and might alarm hundreds of times within a day, making the drivers’sense to become numb, which might finally lead to serious accidents.

In considertion of this,BroadVision developed BroADAS,an intelligent auxiliary driving system. The BroADAS platform has industry-leading cameras as hardware, while integrates the companyundefineds independently developed person identification algorithm technology as software, making it possible for the mobile machine to have a 360-degree monitoring and accurate precaution upon person identification.

Broad Visionundefineds intelligent auxiliary driving system quickly gained the market, and it has been applied on Shanghai Port Group, Singapore Port Authority, etc.

Tailor-made intelligent auxilliary driving system

After the first success, BroadVision used six months to further develop intelligent auxilliary driving system for port heavy lifting equipments. The system monitors the surrounding area of the shorecranes with low latency and high stability, assisting the driver to localize container correctly and precisely hold containers while triggering alarms upon person identification, greatly improving the efficiency of port operations.

Wu Nanhai named the system "BroADAS". Compared to traditional auxiliary driving systems, ADAS has sensors for collecting and analyzing information about the vehicleundefineds surrounding environment, and complex signal processing can be performed as needed to support driving tasks. According to Wu Nanhai, BroADAS system is the only intelligent remote monitoring system built with ADAS concept applied in the port industry, moreover, the system is highly compatible and scalable as other visual systems can be integrated into BroADAS system in the future.

Wu Nanhaiundefineds idea is to develop a monitoring system that can think by itself. "Our monitoring system can autonomously undefinedidentify personundefined, undefinedtrackundefined objects and look left or right. In the mean time, we are doing further research to make the system think by itself by finding the keyholes of containers automatically." Wu Nanhai said: “If this function is achieved, in the 3.2 billion lifting procedures of the worldundefineds 800 million standard containers, 32 billion seconds can be saved. Not only will efficiency be improved, but also fuel emissions can be reduced.”